Executive Summary

Facing escalating development costs and lengthy validation cycles, a leading Level 4 autonomous vehicle company turned to simulation to complement its real-world driving and modernize its testing strategy. Traditionally reliant mostly on physical testing, the company found that this approach could no longer scale to match the complexity, safety requirements, and speed required for advanced AV programs.

To address these limitations, the team adopted a simulation-led strategy, embedding scenario-based simulation and digital twins across the development workflow, including CI/CD. This didn’t replace real-world testing, but complemented it by enabling earlier, faster, and more controlled validation. This allowed their AV developers and verification & validation (V&V) engineers to identify issues sooner, iterate faster, and reduce dependence on late-stage physical testing.

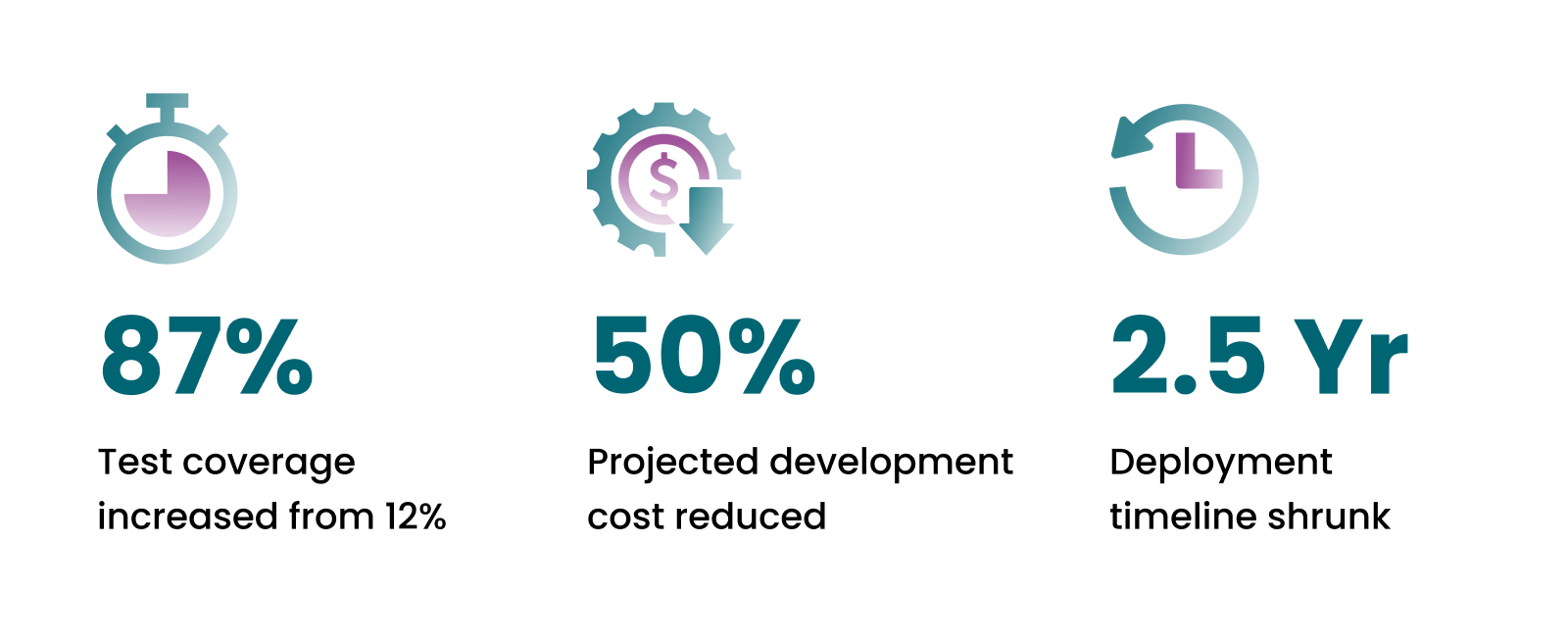

Using Foretellix’s development toolchain, the company shifted a significant portion of testing from the test track to a virtual environment, enabling continuous, high-coverage validation throughout the software lifecycle. The result:

- Test coverage increased from 12% to 87%

- Projected development costs were reduced by 50%

- Deployment timelines shrank from an estimated 4.5 years to less than 2 years

Why Traditional Testing No Longer Scales

As AV programs move toward higher levels of autonomy, physical testing continues to play a critical role, especially in the controlled deployments leading up to removing the safety driver. Most companies will still log tens of thousands or even millions of miles before reaching full driverless operation.

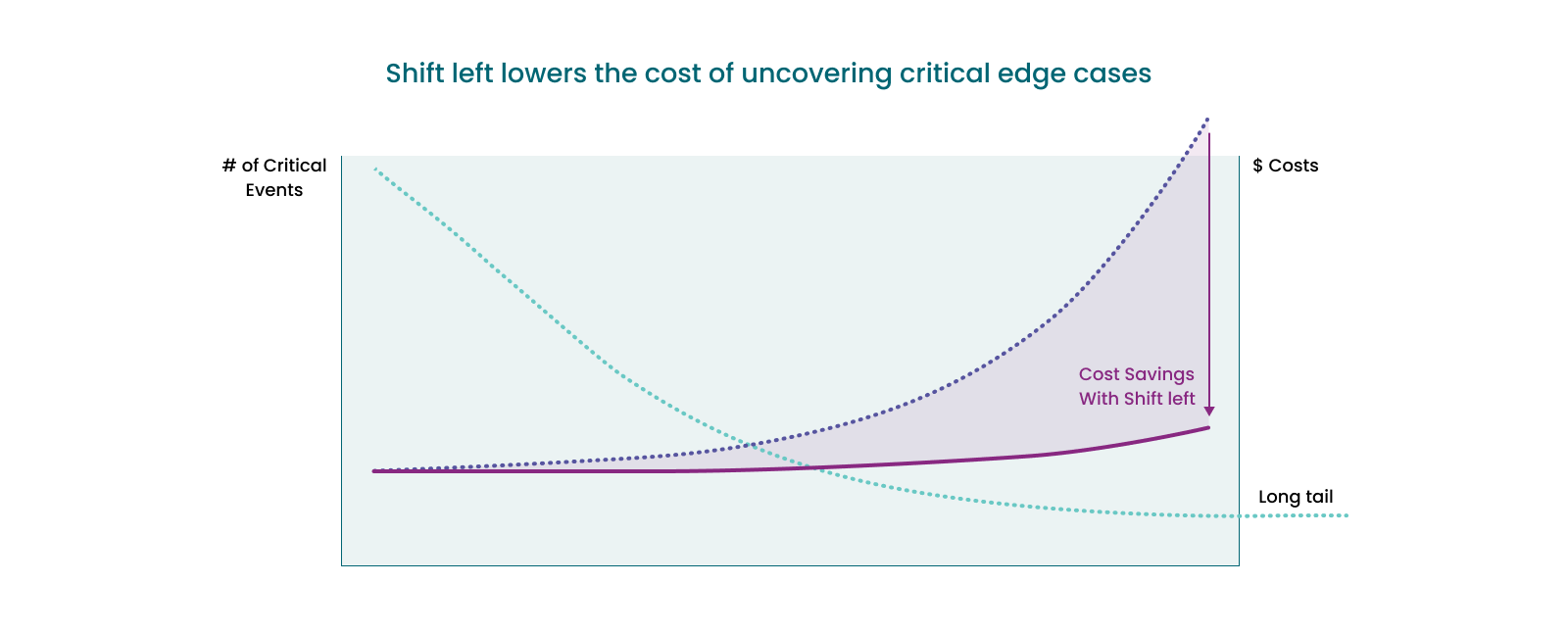

But during development, relying solely on physical testing is increasingly unsustainable. It is expensive, time-consuming, and limited in scope. Reproducing edge cases at scale is nearly impossible, and the long feedback cycles delay issue resolution and slow the entire engineering process. For companies building Level 4 systems, this becomes a significant financial and operational bottleneck.

The cost of inaction is clear: extended timelines, growing validation budgets, and the risk of deploying unverified behavior into safety-critical systems.

This case study explores how one Level 4 AV developer successfully broke that cycle.

The Challenge

A Level 4 AV development team was facing significant challenges common to many AV development programs. Despite having a highly skilled engineering team and a mature software development process, the organization was constrained by a heavy reliance on physical testing. This resulted in long iteration cycles, limited coverage of real-world edge cases, and rising costs as the system scaled in complexity.

Each new software version required extensive regression testing, but validation could only occur after code had already been integrated and staged for deployment testing. By that point, fixing issues often meant reworking large parts of the system. The developers were left without timely feedback, and the validation engineers struggled to keep pace with the frequency of updates.

Simulation was already part of the dev team’s validation toolkit, but it was isolated from the core development workflow. There was no unified process that allowed the developers to easily test code against high-value scenarios as they built it. Without early visibility into system behavior, bugs accumulated and development slowed.

The need for change became clear. The team needed a way to test earlier, scale validation, and empower both developers and verification engineers to work more effectively. They began exploring how to shift testing left, integrating simulation directly into the software development process and enabling continuous scenario-based validation.

Bringing Simulation into Development Earlier

To address these challenges, the company adopted a Shift-Left strategy focused on bringing simulation into the earliest stages of development. Rather than waiting until software had passed through multiple layers of integration, the team integrated scenario-based testing directly into their CI/CD pipeline. This allowed developers to validate changes continuously, using simulation as a fast, repeatable tool for identifying issues before they reached the test track.

Central to this strategy was the use of digital twins. These high-fidelity models recreated vehicle behavior and environmental dynamics in a controlled virtual setting. By embedding the digital twin into the development workflow, the team created a powerful feedback loop where simulation informed design decisions on a daily basis.

Developers and V&V engineers alike benefited from this approach. The developers could run targeted scenario tests as part of their daily workflow, catching regressions or logic errors early. The V&V teams used the same infrastructure to evaluate coverage, prioritize scenarios, and monitor safety-critical performance over time.

Instead of treating simulation as a post-development activity owned solely by validation teams, the company positioned it as a shared asset across development. This organizational change helped reduce costly late-stage failures, improve AV stack quality, and move faster with greater confidence.

Implementation and Methodology

The Shift-Left approach was made possible by a series of deliberate engineering and organizational changes:

- At the core was the integration of Foretellix’s scenario-based simulation tools into the development CI/CD infrastructure. Every code change could now trigger a suite of automated virtual tests, enabling the developers to catch issues early and often.

- Scenario libraries were refined to prioritize relevance and impact. Rather than generating bulk data without clear purpose, the team focused on crafting high-value scenarios tied to real-world performance and historical bug patterns. This targeted approach enabled faster iteration, better resource use, and clearer feedback.

- To scale testing, the company invested in increased compute resources and built internal capacity to support modeling and test development. Foretellix’s tooling allowed them to run simulations in parallel, reaching the volume and diversity required to uncover edge cases and measure performance with statistical rigor.

- Toolchain interoperability was another critical element. Custom scripting layers ensured that simulation outputs could be interpreted consistently across teams, and test results flowed back into development dashboards. This closed the loop between testing and design, giving engineers a clear view of how their changes impacted system behavior.

Over time, the team converged on approximately 31 million simulation runs to reach 87% test coverage. By combining continuous feedback, prioritized scenarios, and deep integration into the development pipeline, they were able to validate design decisions earlier, reduce late-stage risk, and create a framework that could scale with program complexity.

Results

The impact of adopting a Shift-Left strategy was both immediate and measurable. By bringing simulation into the development process and enabling continuous, automated testing, the company transformed how it validated its Level 4 autonomous system.

Test coverage increased from 12% to 87% over a six-month period. This dramatic improvement gave the development team greater confidence in the reliability and safety of the system across a wide range of scenarios, including rare and high-risk edge cases that would have been impractical to recreate physically.

Projected development costs were reduced by 50%. This was driven not only by replacing time-consuming physical tests with faster, more scalable virtual ones, but also by dramatically shortening the program timeline. A program that could have taken up to four years was completed in less than two, saving years of additional engineering, validation, and overhead costs.

AV system performance improved across the board. Early testing helped uncover integration issues and unexpected behaviors before they became systemic. As a result, the company shipped a higher-quality AV stack with fewer late-stage surprises and greater system stability.

Together, these results confirm that simulation-led development is both practical and high-impact for organizations looking to scale AV programs safely and efficiently.

Key Learnings and Takeaways

- Shifting testing earlier in the development lifecycle delivered clear benefits that extended well beyond initial cost and time savings. Rather than replacing physical testing, simulation augmented it, enabling broader test coverage at lower cost, surfacing issues earlier, and reducing dependence on track time for routine validations. This allowed the development teams to focus physical testing on the most safety-critical scenarios, where the highest levels of fidelity were essential.

- By focusing on high-value scenarios, prioritized based on risk and impact, instead of generating large volumes of low-priority tests, the development team was able to increase test relevance and reduce analysis overhead.

- Integrating simulation into the CI/CD pipeline empowered developers to take ownership of validation. They no longer had to wait for verification and validation team testing to understand how their code performed. This shift led to faster debugging, tighter feedback loops, and better alignment between software design and real-world behavior.

- Toolchain interoperability and automated data flows made the testing process repeatable and scalable. Results were consistent across builds, and insights were easier to act on. Verification became part of the development rhythm rather than a separate step.

This case demonstrates what is possible when AV developers adopt a simulation-first strategy where simulation is embedded throughout the workflow, starting early and used continuously alongside physical testing. By shifting testing earlier, integrating simulation into CI/CD, and prioritizing scenario relevance, the company moved from a reactive validation model to a proactive, scalable development process.

Simulation is not just about efficiency. It is about building safer, more reliable systems with fewer resources and greater confidence. As more companies look to scale Level 4 autonomy, the ability to validate early and often will become a baseline requirement.

Foretellix is helping teams make that transition. If you are working on an AV stack for high levels of autonomy and want to explore how simulation can be integrated into your development process and can accelerate your progress, we invite you to get in touch.

Sign up for a demo to see how Foretellix enables AV developers to move faster, test smarter, and build with confidence.